Last summer, PULSED employees had reason to celebrate. The company had its first anniversary and an exciting founding year behind it. As a spin-off from the attoworld - group, PULSED has specialized in ultrashort pulse lasers for infrared spectroscopy and ultrafast laser physics. Dr. Nathalie Lenke is one of the early employees. In the following, she explains how the idea to launch PULSED came about and how the start-up company strives to develop devices for health monitoring and early disease detection.

The company PULSED has been around for over a year now. Where can you place the company in the large landscape of laser technology developers?

That’s right, we celebrated our first birthday at the half-year mark! In the early days, we were busy setting up the company organizationally. But, I think it’s amazing how much you can achieve in just one year and how quickly we grew into a strong team! In the meantime, all the foundation processes have been completed and we already have orders. Compared to long-established laser companies, we are of course still quite small, but our workhorse is a laser system whose parameters are not yet available on the market and which is therefore highly interesting for many research groups. This gives us a technological edge that secures us a place in the market despite great competition!

How did the idea of setting up in this particular niche of photonics come about?

The basic idea had existed for some time. The attoworld - group, from which all current PULSED employees come, is one of the world's leading groups in the field of ultrafast laser physics and has enormous know-how in laser technology development. Because we closely follow the publications and presentations of our international colleagues, we can see both what laser systems are currently available to the community and what laser parameters would be beneficial for their experiments. PULSED was also founded with the idea of making our university group’s laser technology available to a wide range of users outside of attoworld . This allows our customers to focus more on their own experiments and less on laser development.

The final spark then came from the extremely motivating research results around the medical application of molecular fingerprinting. Our longterm goal is to be able to offer devices for medical applications for health monitoring and early disease detection. Of course, this is a task that will keep us busy for a long time, but we are currently in the process of laying a solid foundation for it!

What distinguishes your lasers?

On the one hand, our strength lies in the generation of ultrashort laser pulses with pulse durations of less than ten femtoseconds. This corresponds to pulses shorter than 10–14 seconds and enables measurements with unprecedented time resolution.

What is also special is that these pulses are generated in the infrared. Most (commercial) laser systems generate light at shorter wavelengths or with much longer pulse durations. However, for a number of applications, the infrared range is of great interest because infrared laser light can be used to excite many different molecules in a sample. This makes it extremely interesting not only for medical, but also for a number of other spectroscopic applications.

Moreover, these laser pulses are generated with particularly low “noise” and high reproducibility. This creates an important prerequisite for performing spectroscopic measurements with very high sensitivity. With our phase stabilization technique, the attoworld - group has demonstrated the lowest phase noise ever measured for such lasers. This means that these lasers can generate pulses whose electric fields look exactly the same. This is a basic requirement for many experiments.

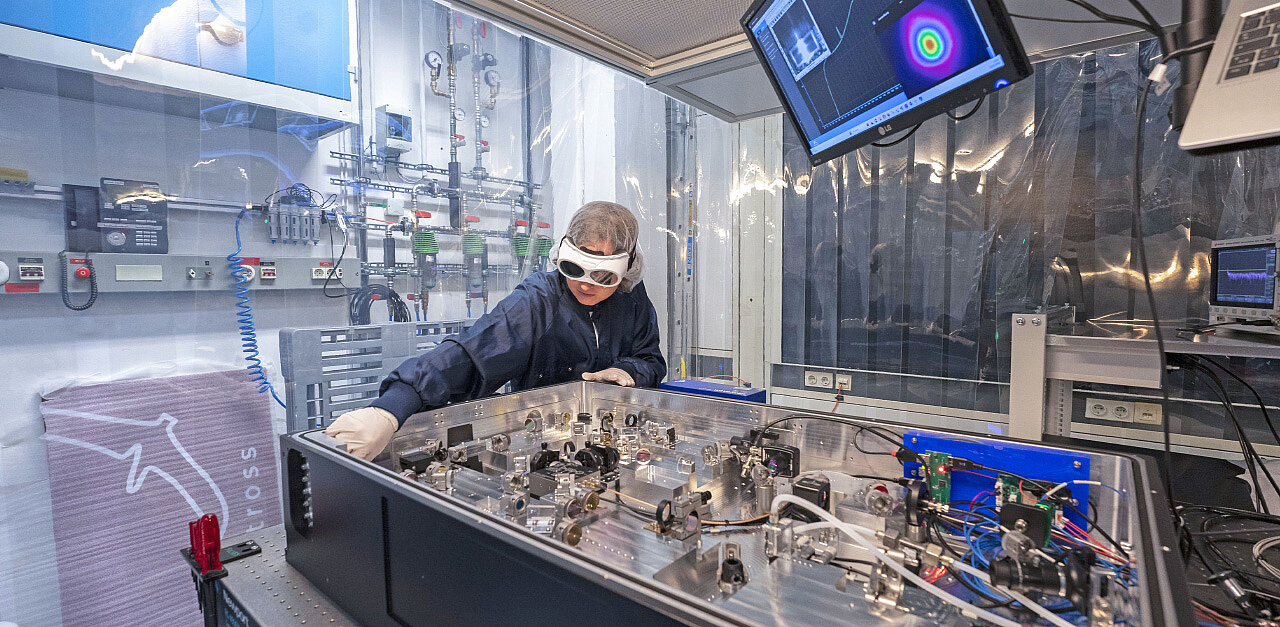

Last but not least, it is also the compact and extremely robust design that distinguishes our lasers. We place a lot of emphasis on the mechanical design of the laser in order to provide users with a user-friendly system that is as maintenance-free as possible.

Can you describe how your lasers work?

The heart of our system is a laser crystal made of chromium-doped zinc sulfide (Cr:ZnS), which we irradiate and optically excite with a commercial laser. The crystal is located in a so-called resonator – an array of mirrors with special coatings. This “traps” the light emitted by the crystal so that the light passes through the crystal several times and gets amplified. To generate high-intensity light pulses, we then need to put the laser into pulsed mode by rapidly moving a resonator mirror. Finally, to use the light pulses for experiments, a mirror in the resonator is partially transparent, such that a small part of the light can escape from the resonator. The light pulses obtained are already very short, but their spectrum is not yet broad enough to perform phase stabilization with them. Therefore, the light is passed through another crystal to broaden the spectrum, giving it more spectral components (more infrared “colors”). Specially coated mirrors ensure that all these spectral components remain compressed in a short pulse. The last element of the laser deals with phase stabilization, which ensures that the electric field of each laser pulse looks exactly the same. But to explain this element in more detail, you'll have to come visit us in the lab!

How long does it takes to develop such a technology?

It takes years for research to lay the necessary foundations. Only then can you take the second step and convert existing structures into more compact, more stable and easier-to-operate systems. In technical jargon, this is referred to as passing through the “Technology Readiness Levels” (TRLs). In university research, one usually gets to TRL 4 or 5, i.e. one provides experimental “proof of concepts” and has built first demonstrators. All further steps up to TRL 9, i.e. a certified and saleable product, are then the task of companies like PULSED and require another 1–2 years.

Which users are interested in your laser developments?

On the one hand, there are the groups from university research, which are primarily interested in our special laser parameters. They are targeting applications in the field of infrared spectroscopy and ultrafast laser physics. On the other hand, we have already had discussions with large companies in the field of infrared spectroscopy and laser technology. They show interest in combining our light source with existing setups from their own product range.

And we are looking at blood-based and minimally invasive health monitoring for early disease detection as a particularly promising application that is also being pursued in the attoworld - group (together with the Center for Molecular Fingerprinting). In the long term, we are targeting this market of medical applications, where we see great growth potential.

Do you have plans for the future?

We are happy that we will not run out of work in the near future! At the moment, we are well occupied processing our current orders. This will allow us to establish ourselves well in the highly competitive and constantly growing photonics market. In addition, we want to continuously expand our product range as well as our customer base by offering modular extensions to our laser system in the future. This should not only extend the spectral range and increase laser power, but also enable field-resolved spectroscopic measurements with high sensitivity.

Together with the long-term goal of opening up medical applications, we have a lot planned – both in research and in product development. To make it all happen, we are always looking for new colleagues to join us. We welcome anyone who contacts us and shows interest in working with us to accomplish these tasks! Exciting times are ahead at PULSED!